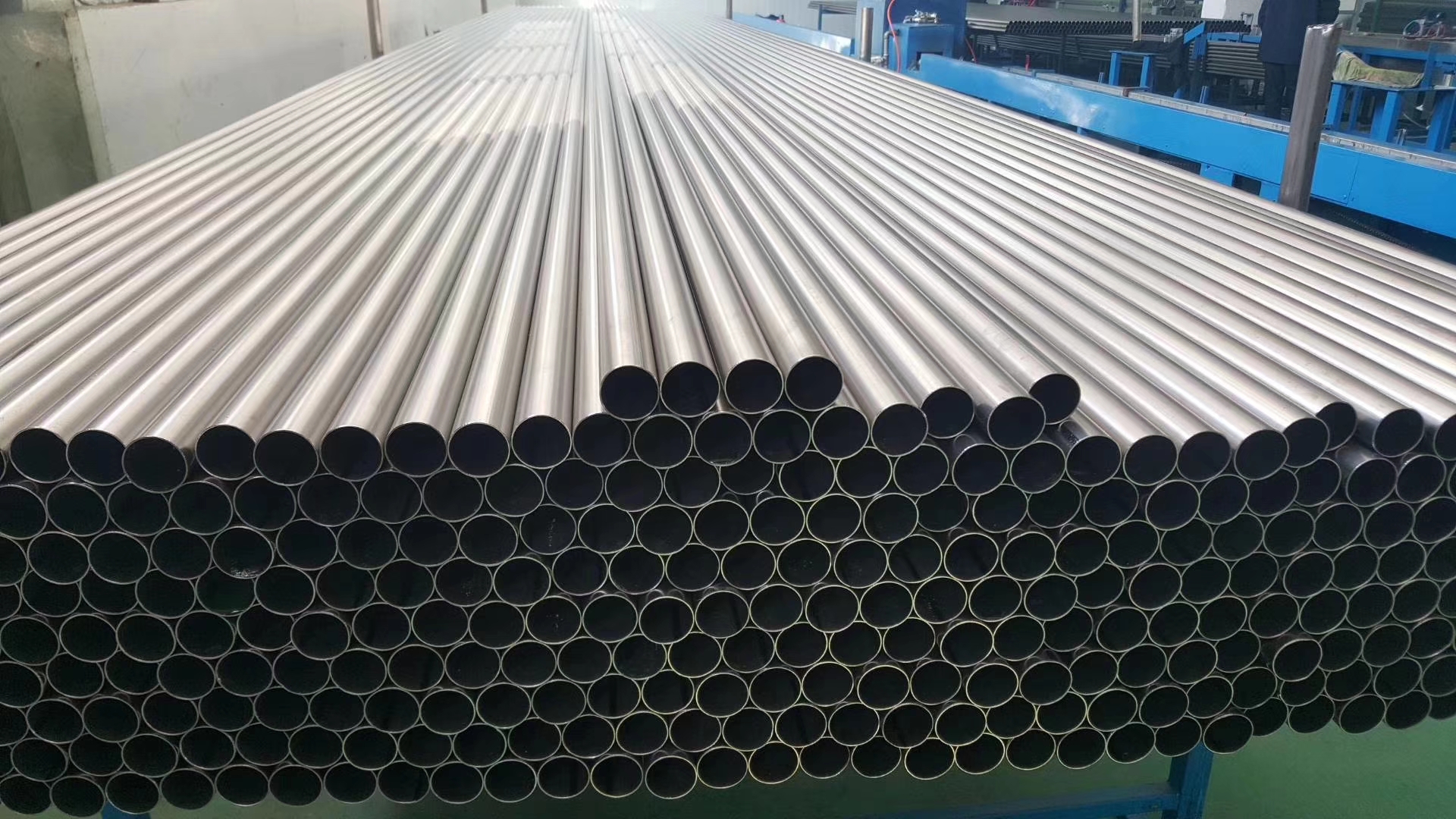

Titanium Wire Titanium Welding Wire 3D Printing Wire GR5 Ti Wire Hanging Wire Ø0.8-1.2mm 10Kg

SKU: 98795-1 Brand: Titanium MaterialMaterial : Titanium GR5, CP Titanium

Dimensions : Diameter :0.8mm/1mm/1.2mm

Shipping : UPS/DHL

Quantity : 10KG GR5 Titanium Wire

$1199 – $1399

Rison Titanium Wire Specifications :

Name : Titanium Wire Titanium Welding Wire Rison Titanium Wire GR5 Titanium Wire

Brand: Rison Titanium

Size : Diameter 0.8mm/1mm/1.2mm

Weight : 10Kg

Material : GR5 Titanium

Package : 10Kg Titanium Round Wire

Specialty : RISON-Titanium Has Been Focusing on Titanium Products for Ten Years

Qualification : American Titanium Industry Association Member

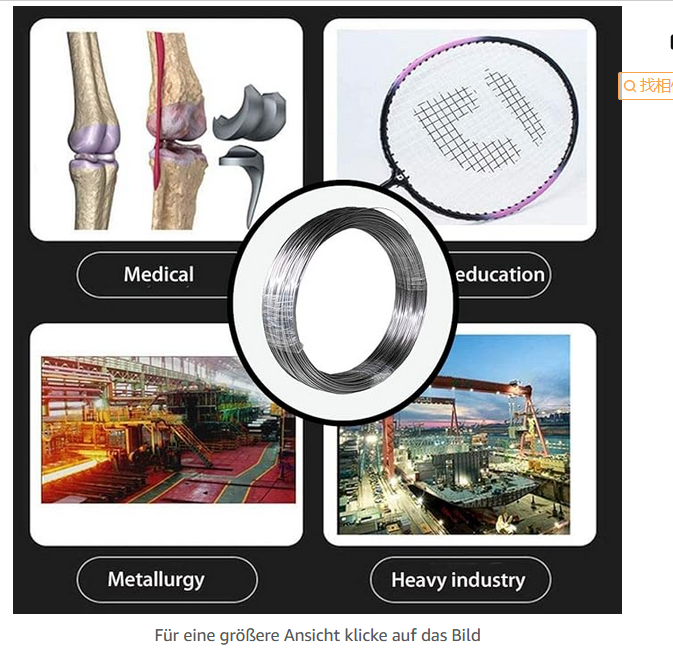

Application:

Titanium Grade 5 (Ti-6Al-4V) wire is widely used in various applications due to its excellent

combination of high strength, low density, and corrosion resistance.

Some common applications of titanium GR5 wire include:

Aerospace and Aircraft Industry: Titanium GR5 wire is commonly used in aircraft components,

such as fasteners, springs, wires, and brackets, due to its lightweight properties and high

strength-to-weight ratio.

Medical Implants: Titanium GR5 wire is biocompatible and non-toxic, making it suitable

for medical implants such as orthopedic pins, screws, and bone plates.

Automotive Industry: Titanium GR5 wire is used in the automotive industry for components

that require high strength and corrosion resistance, such as exhaust systems, springs,

and engine components.

Marine Applications: Titanium GR5 wire is resistant to corrosion in marine environments,

making it ideal for use in marine equipment, seawater pipes, and offshore structures.

Sports Equipment: Titanium GR5 wire is utilized in the manufacturing of sports equipment

such as bicycle parts,tennis rackets,and golf club shafts due to its high strength and durability.

Chemical Processing: Titanium GR5 wire is commonly used in chemical processing industries

for manufacturing equipment such as valves, fittings, and heat exchangers due to its excellent

corrosion resistance.

Jewelry: Titanium GR5 wire is also used in the jewelry industry to create durable and lightweight

jewelry pieces.

Overall, the versatility of titanium GR5 wire makes it a popular choice for a wide range of

applications across various industries.

Applications of 3D printing titanium wire:

Medical Implants: Titanium wire 3D printing is utilized in the medical field to manufacture

custom implants tailored to individual patients, including bone implants, dental prosthetics,

and orthopedic devices and so on . What’s more the biocompatibility and corrosion

resistance of titanium make it a suitable material for medical applications.

Automotive: The automotive industry utilizes 3D printed titanium wire for producing lightweight

components such as brackets, heat exchangers, and customized parts.

Tooling and Manufacturing: Titanium wire 3D printing is used to create tooling and molds

for manufacturing processes such as injection molding and die casting.

Defense and Military: 3D printing titanium wire is used in the defense sector to manufacture

military equipment, such as armor plates, missile components, and drone parts and so on.

The high strength and ballistic performance of titanium make it suitable for defense applications.

Energy Industry: Our Rison Titanium wire 3D printing is applied in the energy sector for producing

components used in power generation, including heat exchangers, turbine parts, and other critical

components.

The corrosion resistance of titanium is advantageous for handling harsh environments in energy

production.

Research and Development: Titanium wire 3D printing is also used in research and development

to create prototypes, test pieces, and experimental components due to the flexibility and speed

of additive manufacturing technology.

Features:

1. Light Weight : GR5 Titanium Wire is 30% Stronger Than Steel and Almost 50% Lighter

2. Good heat resistance : GR5 Titanium Round Wire can be used for a long time at a

temperature of 600*C or higher.Usually aluminum loses its original properties at 150°C and

stainless steel at 310°C.

3. No Rust : Rusting is an oxidation reaction, but Titanium is very inactive and difficult to be oxidized

anyway. So titanium Hanging Wire metal nearly no rust. And titanium alloy can be kept as new for

tens of thousands of years.

4. Good Low-temperature performance : some titanium alloys strength (such as Ti-5AI-2.5SnELI)

increases with the decrease of temperature. They still have good ductility and toughness at low

temperatures.

5. Shape memory function: It refers to the ability of Ti-50% Ni (atomic) alloy to recover its

original shape under certain temperature conditions.

Why choose our company?

Our advantages are mature technology, advanced equipment and high product quality.

All the raw materials and finished parts are inspected by the authoritative third-party testing

institutions to ensure quality.Moreover We always believe that customer’s satisfaction is the

biggest driving force for the company’s development.

Quality assurance : Our Titanium Wire Titanium Welding Wire 3D Printing Wire GR5 Ti Wire

Hanging Wire Quality Inspected Before Shipping

We Manufacture our titanium products in Strictly Accordance with ISO9001:2015& AS 9100 :2018

standard.At the same time our company is an enterprise star in our local city.

All the time we manufacture All products on the basis of international standards: EN, AMS, ASTM,

ASME,JIS,etc; Our company can customize all the products according to the customer’s drawings;

Moreover we can design the products according to thethought of customers,if customers do not

have drawings or samples.

We can customize all titanium products (color/size and so on) ,you can contact us if you have

special requirements.

Tips : The Customs Clearance Fee Shall Be Borne By the Buyer

If you have any questions, please feel free to contact us. We will reply you within 24 hours.

There are no reviews yet.