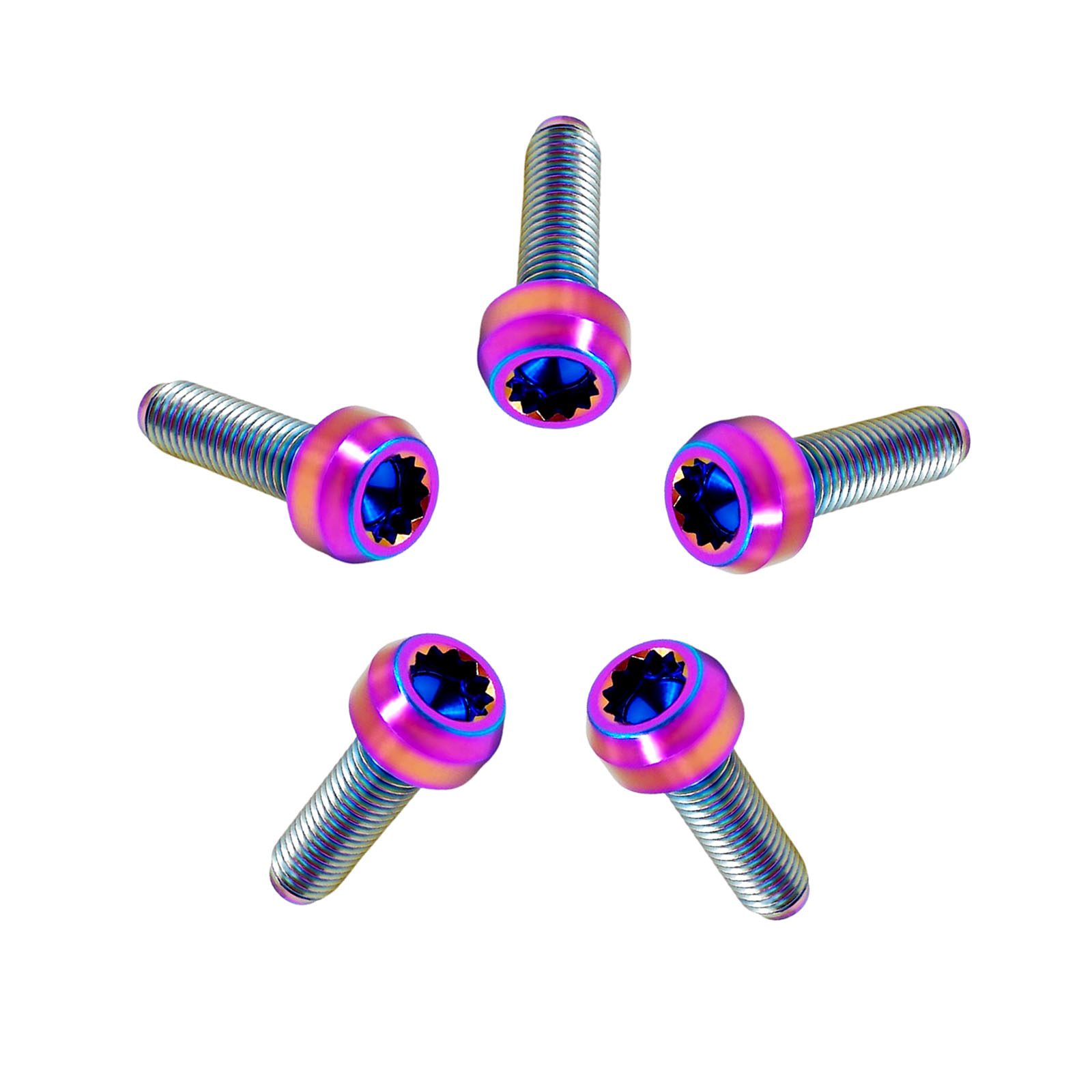

Rison Titanium 12 Point Socket Bolts

Introduction

In high-stakes engineering environments, fastener selection directly impacts performance, safety, and longevity. Specifically, Rison Titanium 12 Point Socket Bolts merge aerospace-grade titanium’s advantages with the unique benefits of a 12-point drive system. Consequently, these bolts deliver unparalleled reliability where weight savings, corrosion resistance, and high torque transfer are non-negotiable.

Key Advantages & Material Science

Fundamentally, Rison employs certified Ti-6Al-4V (Grade 5) titanium alloy, enabling transformative benefits:

- Superior Strength-to-Weight Ratio: Titanium offers strength comparable to high-grade steel while being 45% lighter. Thus, it dramatically reduces mass in dynamic systems.

- Corrosion Immunity: A passive oxide layer grants exceptional resistance to saltwater, chemicals, and acids. Therefore, these bolts excel in corrosive environments where steel would fail.

- 12-Point Drive Efficiency: Unlike standard hex sockets, the 12-point design allows 30° engagement (vs. 60° for hex). As a result, it enables faster assembly/disassembly in confined spaces and higher torque application with reduced slippage risk.

Critical Application Areas

1. Aerospace & Aviation

Primarily, these bolts secure turbine blades, engine housings, and flight control systems. For instance, their lightweight nature directly enhances fuel efficiency in airframes. Additionally, the 12-point drive ensures secure torque transfer in vibration-intensive zones like landing gear. Moreover, titanium’s non-magnetic properties prevent interference with avionics.

2. High-Performance Motorsports

In this sector, Rison bolts anchor turbochargers, suspension linkages, and drivetrain components. Notably, reduced rotating mass improves acceleration and handling. Simultaneously, the 12-point socket withstands extreme torque during track-side maintenance, whereas standard fasteners may strip.

3. Marine & Offshore Systems

Given prolonged saltwater exposure, titanium’s corrosion resistance is indispensable. Typically, these bolts secure sonar equipment, propeller shafts, and subsea robotics. Furthermore, the 12-point drive simplifies underwater tooling operations where maneuverability is limited.

4. Medical & Imaging Technology

Owing to titanium’s biocompatibility and non-magnetic nature, these bolts assemble MRI machines, surgical robots, and implantable devices. Importantly, the flush 12-point head minimizes protrusions in sterile environments.

5. Energy & Industrial Systems

In demanding settings like wind turbines or nuclear facilities, Rison bolts provide corrosion-resistant fastening for critical panels and sensors. Significantly, their high fatigue resistance ensures integrity under cyclic loads.

Rison’s Engineering Excellence

Beyond material superiority, Rison guarantees:

- Precision Manufacturing: Through CNC machining and thread rolling, bolts achieve ISO 4762 dimensional compliance. Hence, they ensure perfect fitment.

- Surface Engineering: Options like anodizing (gold, blue, black) not only reduce galling but also enhance wear resistance. Conversely, passivation maximizes corrosion protection.

- Galling Mitigation: Since titanium is galling-prone, Rison pre-treats bolts and provides installation lubricants. Thus, users avoid cold welding during torque application.

- Customization: While standard sizes are stocked, Rison readily supports custom lengths, drives, and threads.

Implementation Considerations

Although titanium bolts cost more upfront, their lifecycle value—including weight savings, zero corrosion maintenance, and extended service life—ultimately reduces TCO. However, proper installation is critical: always use calibrated tools and titanium-specific anti-seize lubricants. Similarly, verify mating components (e.g., nuts) to prevent galvanic corrosion.

In summary, Rison Titanium 12 Point Socket Bolts represent a paradigm shift for mission-critical applications. By combining titanium’s material excellence with the 12-point drive’s functional advantages, they solve weight, corrosion, and torque challenges that conventional fasteners cannot. Ultimately, whether launching satellites or racing at Le Mans, Rison delivers the secure, lightweight foundation modern engineering demands.

Conclusion:

In conclusion,Rison Titanium Tapered Socket Cap Bolts are more than just fasteners; they

are a strategic engineering choice for applications demanding the ultimate combination

of low profile, high strength, minimal weight, and exceptional environmental resistance.

From the skies to the sea, from the racetrack to the operating room, and deep within

precision machinery, these bolts provide a secure, reliable, and high-performance

foundation. When space is tight, weight is critical, and failure is not an option,

Rison’s titanium tapered socket cap bolts deliver the engineered solution.

Please refer Rison Titanium Tapered Socket cap Bolts.

Our brand is Rison Titanium , We have many Grade 5 (Ti-6Al-4V) titanium Nuts, pls click

Rison Titanium to place the order if need any titanium bolts. Also we can custom made

any titanium bolts nuts .

Rison Titanium is a very professional company ,what’s more we are specialized in the production

of Titanium more than 13 years. As well as we are the American Titanium Industry Association

Member. Our Rison titanium GR5 products Quality Inspected Before Shipping .

What’s more our company Manufacture in Strictly Accordance with ISO9001:2015& AS 9100 :2018.