DIN 934 Titanium Hexagon Nuts

In the world of precision fasteners, DIN 934 titanium hexagon nuts have emerged

as an indispensable component, not only meeting stringent German industrial

standards but also redefining performance benchmarks. While conventional

steel nuts remain widely used, however, titanium variants are rapidly

becoming the preferred choice for critical applications. To fully appreciate

their superiority, let us examine their key attributes and industry advantages.

First and foremost, manufacturers produce DIN 934 titanium nuts with

exacting dimensional accuracy, ensuring perfect compatibility with

corresponding titanium bolts. Unlike standard nuts that may require

additional machining, by contrast, these precision-engineered components

maintain consistent thread profiles across production batches.

Consequently, mechanical engineers specify them for assemblies

where even micron-level variations could compromise integrity.

Moreover, the titanium alloy composition delivers exceptional material benefits.

Specifically, Grade 5 titanium (Ti-6Al-4V) provides a tensile strength of

900 MPa while simultaneously offering 45% weight reduction versus steel

equivalents. As a result, aerospace designers prioritize these nuts for

airframe construction, where every gram saved translates directly to

enhanced fuel efficiency.

More Details

In addition to their mechanical advantages, DIN 934 titanium nuts exhibit

unparalleled corrosion resistance. Not only do they withstand saltwater

immersion in marine applications, but they also resist chemical exposure

in pharmaceutical and food processing equipment. For instance, offshore

wind turbine manufacturers report significantly extended maintenance

intervals after adopting titanium fastening systems.

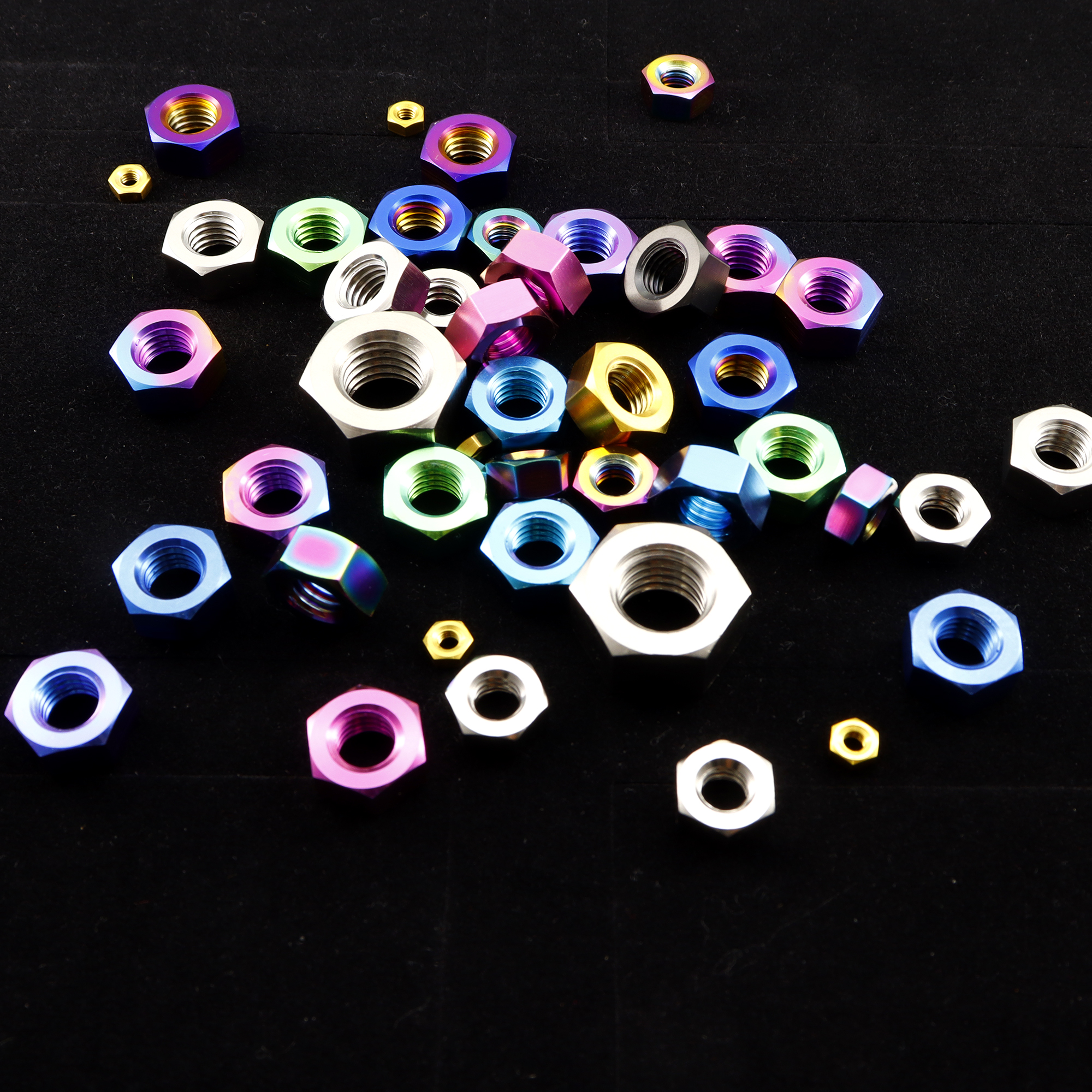

Furthermore, the surface characteristics of these nuts enhance their

functional performance. Manufacturers apply specialized anodization

treatments that create durable, wear-resistant surfaces while enabling

color-coding for easy identification.

Maintenance teams value this feature, as it simplifies visual inspections

in complex machinery.

Transitioning to installation benefits, these hex nuts demonstrate

superior thread engagement properties. Because titanium possesses

natural anti-galling characteristics, installers experience 40% less

friction during tightening compared to stainless steel. Subsequently,

assembly operations achieve greater efficiency with reduced tool wear.

Examining thermal performance, DIN 934 titanium nuts maintain structural

stability across extreme temperature ranges. Whether subjected to

cryogenic conditions or engine compartment heat, they retain clamping

force where conventional materials fail. Automotive engineers confirm

this through rigorous testing, including 10,000 thermal cycles with zero

performance degradation.

Rison Titanium Nuts

From a sustainability perspective, titanium fastening systems offer

significant environmental benefits. Not only are they fully recyclable,

but their extended service life reduces replacement frequency and

waste generation. Environmentally-conscious manufacturers

increasingly select them to support green manufacturing initiatives.

Finally, in specialized applications, these nuts provide unique advantages.

The non-magnetic properties make them ideal for MRI equipment

and sensitive electronics, while their biocompatibility allows use in

medical implants. Research laboratories utilize them in particle

accelerators where material purity is paramount.

In summary, DIN 934 titanium hexagon nuts represent the perfect

synergy of German engineering precision and advanced material

science. As industries continue pushing performance boundaries,

these components stand prepared to meet evolving demands

across aerospace, marine, energy, and medical sectors. Their

unmatched combination of strength, lightness, and durability

establishes them not merely as an alternative, but as the new

paradigm in high-performance fastening technology.

About Rison Titanium

We are the American Titanium Industry Association Member .

Moreover We always believe that customer’s satisfaction is the biggest driving force for the

company’s development.

We Manufacture our Rison Titanium Hex Nuts in Strictly Accordance with

ISO9001:2015& AS 9100 :2018 standard.

Tips :

Buy with Confidence, Over 60,000 Titanium Products in Stock, Ship within 1-2 working days.

Please click Rison Titanium Nuts DIN 934 Nuts to place the order if you want.

The Customs Clearance Fee Shall Be Borne By the Buyer.

Moreover, we can customize all titanium products (color/size and so on) ,you can

contact us if you have special requirements.

If you have any questions, please feel free to contact us. We will reply you within 24 hours.