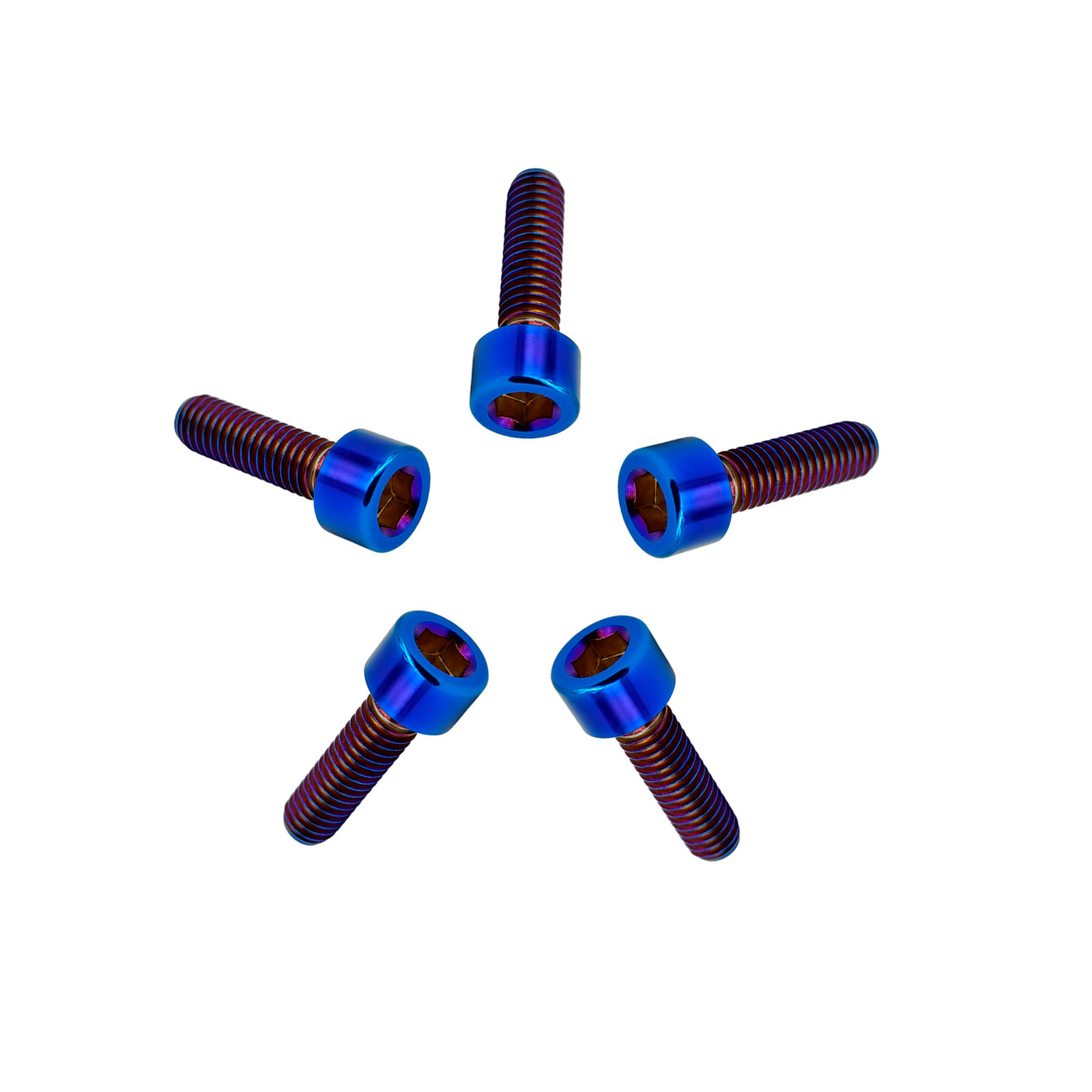

DIN 912 Titanium Socket Head Cap Bolt Screws Introduction

DIN 912 titanium socket head cap screws (SHCS) represent the pinnacle of high-strength,

lightweight fastening technology. Engineered to comply with the rigorous

DIN 912 / ISO 4762 standard, our Rison Titanium DIN 912 Titanium Socket Head Cap Bolt

feature an internal hex drive and cylindrical head design, delivering exceptional

reliability in space-constrained, high-stressapplications and so on. Machined from

aerospace-grade titanium alloys, they are indispensable in industries where

corrosion resistance, weight savings, and structural integrity are non-negotiable.

Rison Titanium Socket Bolts Key Features & Specifications

1. Material Excellence

- Titanium Alloys:

- Grade 2 (CP Titanium): Ideal for marine/chemical corrosion resistance.

- Grade 5 (Ti-6Al-4V): High strength (≥895 MPa UTS) for aerospace/automotive.

- Critical Advantages:

- 45% lighter than steel equivalents.

- Immune to saltwater, acids, and chlorides.

- Non-magnetic & biocompatible (ISO 5832-2).

2. DIN 912 Design Attributes

| Feature | Specification |

|---|---|

| Head Style | Low-profile cylindrical head with internal hex drive |

| Thread Standards | Metric coarse/fine (M1.6 to M64) |

| Drive Size | Hex key (Allen) driven – sizes 0.7mm to 36mm |

| Property Class | 8.8, 10.9, 12.9 (steel strength equivalent) |

| Surface Finish | Polished, anodized (color-coded), or bead-blasted |

3. Performance Advantages

- Space Efficiency: Flush mounting avoids protrusions in tight assemblies.

- High Torque Transmission: Hex socket minimizes slippage vs. external drives.

- Vibration Resistance: Uniform load distribution reduces loosening risk.

- Temperature Range: Stable from -250°C to 400°C (–418°F to 752°F).

Industrial Applications

Where DIN 912 Titanium Bolts Excel

- Aerospace:

- Aircraft engine mounts, avionics enclosures, and satellite frame assemblies.

- Medical Devices:

- MRI machines, surgical robots, and implantable device housings (biocompatible Grade 23).

- Automotive Motorsports:

- Lightweight engine blocks, carbon-fiber chassis, and turbo systems.

- Marine Engineering:

- Subsea robotics, desalination plants, and sailboat rigging.

- Precision Machinery:

- CNC equipment, optical instruments, and semiconductor manufacturing tools.

In summary,Titanium DIN 912 Bolts can used in many diffferent field.

Advantages vs. Conventional Steel Bolts

| Parameter | DIN 912 Titanium Bolt | Steel SHCS |

|---|---|---|

| Weight | ⬇️ 45% reduction | Heavy |

| Corrosion | ⬆️ Passive oxide layer resists all rust | Requires coatings (e.g., zinc) |

| Tool Access | ✅ Low-profile head fits confined spaces | Larger head height |

| Thermal Expansion | ≈50% less than steel | High expansion risks loosening |

| Fatigue Strength | Superior under cyclic loading | Lower endurance limit |

Installation Best Practices

- Anti-Galling Protocol:

- Use titanium-specific lubricants (e.g., molybdenum disulfide paste).

- Avoid overtightening – torque to 75% of steel bolt values.

- Tool Selection:

- Precision-ground hex keys (ISO 2936) to prevent socket rounding.

- Anodized Variants:

- Type II/III anodizing enhances wear resistance and allows color-coding for assembly verification.

Conclusion: Engineering Perfected

DIN 912 titanium socket head cap screws merge German precision standards with the revolutionary

properties of titanium. They solve critical challenges in modern engineering:

- Weight reduction without sacrificing strength.

- Corrosion-free operation in hostile environments.

- Maximized space utilization in compact designs.